2011 CBR250RR

Honda MC22 CBR250RR

September 2011

This will be the third MC22 'Project' we've done. Frankly speaking, our starting point was actually the same bike which we used in our previous two projects, the RC211V and the T8 which can be seen on other pages of this website. MC22s are getting hard to find nowadays in Thailand so it is easier to rework our existing bike than to start from scratch. That is our excuse anyway for pulling apart the perfectly good and finished project bike and making it into another perfectly good and finished project bike...

The MC22 is a great bike in many ways. If you look at the engine and frame unit on an unassembled bike, you could be forgiven that it belonged to a superbike with its four cylinder twin cam engine, piggy back gearbox hugged by the beautifully sculptured cast and extruded frame. It is only when you start putting the dangly bits on the frame that the bike starts to show that it was built to a lower spec with low performance in mind. True, it was given a gull arm and twin rotors, but the weedy 39 mm. non adjustable forks and the baby calipers, while adequate are not going to impress anyone, especially the rider under race conditions. Move to the rear and as well as a basic rear shock, you have a rear wheel that looks like it would belong on the front of most bikes being only 4 inches wide and sporting a 140 section tyre. This has always bothered me. I know it is not exactly a superbike and the set up is good for quick changes of direction but it doesn't look right and ever since our good friend from Motomorphic, Jim Davis, put a Honda RS250 front end and rear wheel on his bike I've been wanting to do the same. That was ten years ago... Eventually, I persuaded Matt to do the same to our cbr and eventually during a lighter week or two in his hectic schedule he has created the bike you see here on this page. (Did have a little help of course! - Matt.)

If we start from the front and work our way back, you will see that the front end is nothing like the original MC22 one. We did actually have the complete RS250 front end fitted at one point but realising we didn't have a triple clamp design ready and that the RS forks are quite short, we changed our plan and decided on the tried and tested NC35 RVF400 forks. These were clamped to a set of NC35 TYGA CNC upper and lower triples but with a special custom stem and steering stoppers to fit the MC22 frame, and the whole lot secured by a TYGA aluminium steering stem nut. With trial fitting it was obvious that there was not a lot of clearance for handlebars with the bodywork on full steering lock. We solved this by fitting a pair of VJ22 handlebars instead of the TZR250 ones we had initially earmarked which were more radically sloped downwards. Next Matt machined a custom key lock holder so that it could sneak into the given space between the NC35 triple and the CBR frame. To our surprise, it even still functions as a steering lock which was a bonus. There were then other challenges fitting throttle cables and switchgear given the limited space given by the new lower bars. With a bit of patience and juggling around, we eventually got everything to clear and to work, as well as look like the bike had been rolled out of Hamamatsu factory in this spec.

The front wheel is a 3.75 inch magnesium Marchesini off an RS250 GP bike. Being only .25 inch narrower than the original rear, we were a bit apprehensive that it would look a ridiculous but once the 120/70 tyre was fitted and the wheel installed with some one off spacers , it looks the part. The wheel is fitted with a pair of our rotors and is grabbed by a pair of SP2 Nissin calipers. Lines are braided and the master is a 14 mm NSR250 one with a carbon mini reservoir fitted for effect and to keep the dash uncluttered. This pretty much completes the front end.

Moving to the rear, our goal was to get a wider wheel in and to do so, it was obvious that the stock swing arm was way too narrow. An MC21 NSR250 one would be the obvious choice if it were not for the sloped rear shock position and it came down to the two CBR400RR swingers of which we choose the NC23 in the end because we had one at hand and it looks nice and chunky. The conversion is not particularly difficult and the pivot points and linkages are all in the correct place. It is then a case of choosing the correct components, making bushes and spacers and getting everything to fit. The rear shock is a custom made one by Matt. He did his usual lego inspired act of building a shock out of suitable parts from various ones he had sitting around the workshop and we now have a three way adjustable remote gas rear shock worthy of any superbike. Just to show it off, he painted the spring gloss white and fitted some nice anodised braided fittings. It retains the stock CBR250RR valve, with a little adjustment to the shimming, but the rest is basically a mixture of CBR250, NSR250 and NC30.

Before fitting the rear wheel, there were further modifications done to the swing arm. Various protrusions from the castings such as the chain guard lugs were removed and the whole unit polished to remove the cast finish, followed by a going over with scotchbrite to get the brushed effect you see now. The 'mud flap' on the stock undertray needed a little surgery to avoid collision too. Finally holes were drilled and mounts made for the rear stand bobbins and the RS250 rear caliper torque arm. We were now ready of the rear wheel. This is also a magnesium Marchesini and is probably the widest wheel anyone has attempted to put into a 250. Well, we had already done a similar conversion to the NRS and the NC23 swing arms and MC21 swing arms are almost identical dimensionally so we were confident of this bit of the job. A special spacer was made so we could use our CNC sprocket holder. This is installed with an AFAM rear sprocket. The bike now runs a 520 chain with a ZXR250 front sprocket to match the spline shaft and the chain. On the other side of the wheel, with our swing arm already prepared, it was a relatively straight forward job of fitting an RS250 rear rotor, mini underslung caliper and torque arm. The tyre is fitted with a 160 section tyre and there is clearance and proper alignment for the chain all the way to the front sprocket and back which is part luck and part careful measurement.

The pipe is stock with our carbon silencer bolted on, but the mount has been cut and repositioned to allow the pipe to clear the swingarm

The step kit shown here is a new product and is designed for a stock bike. With careful spacing to clear the wider swing arm we were able to get this kit to fit our project bike and show how the kit looks when fitted on a bike. The irony is, that it is designed for a stock swing arm so actually looks even better on a stock bike. The left heel guard is included in the kit but the right side one is actually designed for a GSX-R K9 but fits perfectly and suits the kit and in keeping with the other side. The brake is fitted with an HRC reservoir kit. This completes the chassis mods.

Moving to the aesthetics, the bike is obviously fitted with one of our body kits. This is the T8 kit with a lower screen to give it a lower appearance. The kit consists of everything you need to replace the old 90s style bodywork with something up to date. It uses the stock subframe but is supplied with a new meter stay and we fitted a new upper/mirror stay as a matter of course. The kit is practical as well as stylish and there is still a lockable luggage compartment. It uses stock mirrors but the headlight and tail lights are included and update the looks of the bike. The headlight bulbs are halogen and the taillight LED. The bodywork is finished in a yellow metallic with black wing and underside. The front fender is an RC211V style carbon one for the NC35 front end. There are other carbon touches such as the tank filler and the instrument surround as well as the already mentioned carbon heel guards on the step kit.

This bike has our tank cover fitted. The cover fits neatly over the original tank and this has the benefit of not only protecting from or hiding accident damage, but it means that we can supply you a complete painted kit including tank cover so there is no messing around waiting for paint or looking for another tank while you are using your bike.

Performance of the bike is pretty similar to how it was before if you just measure things such as speed. However, the bike now has a lot more grip, better ride, more ground clearance and a lot sharper brakes. It is all ready now for more power to make it a fun track day tool as well as an everyday commuter/back lane sprinter. As I mentioned earlier, it is really an ideal candidate for a turbo and we have already got all the parts. We just need to find some time for poor old Matt to install and develop the modification. As we always say, watch this space for more updates! (I will get it done....honest! - Matt.)

Finally our other 2 available paintschedules for the T8 Bodywork kit (photos send to us by our customers)

Silencer, Carbon, Round, Slip On, CBR250RR MC22, Assy.

Silencer, Carbon, Round, Slip On, CBR250RR MC22, Assy. This easy to fit bolt on silencer replaces the stock heavy…

- Model

- EXSL-0016

- Quantity

- 100+

Kit, Complete Body Set, Street, MC22 T8

Kit, Complete Body Set, Street, MC22 T8 This set of bodywork comprises all the bodywork parts including the passenger seat cover…

- Model

- BPFS-0052

- Quantity

- 1

Racing Step Kit, MC22 CBR250RR

Racing Step Kit, MC22 CBR250RR Designed and built in-house by TYGA Performance using CAD/CAM software, these CNC machine- made step…

- Model

- STAA-0011

- Quantity

- 12

Carbon Meter Cover MC21, MC22, NC35, NC29, SC28

Carbon Meter Cover MC21, MC22, NC35, NC29, SC28 Attractive carbon cover suitable for MC21, MC22, NC35, NC29, SC28 meter assembly.…

- Model

- BPCC-0004

- Quantity

- 3

Front Fender, Carbon, NC35, 2006 RC211V style

Front Fender, Carbon, NC35, 2006 RC211V style Attaches to the original NC35 RVF400 mounting points and can be used with…

- Model

- BPCF-9005

- Quantity

- 2

Carbon Tank Filler Cap Cover Honda

Carbon Tank Filler Cap Cover Honda Carbon Tank Filler cap Cover. Fits most Honda sports bikes including: …

- Model

- BPCC-0002

- Quantity

- 5

Upper/Mirror Stay, stock shape, MC22

Upper/Mirror Stay, stock shape, MC22 Upper / Mirror Stay for MC22. Direct replica of the standard stay for simple replacement…

- Model

- TYLY-0036

- Quantity

- 6

Mini brake reservoir, Carbon

Mini brake reservoir carbon This mini brake reservoir is the perfect final touch for a race or show…

- Model

- BPAC-0005

- Quantity

- 3

Heel Guard, Right Only, Carbon

Heel Guard, Right Only, Carbon Right side carbon fibre heel guard. It can be fitted to many other models, being suitable for…

- Model

- BPCC-9010R

- Quantity

- 100+

HRC Brake Reservoir Kit

HRC Brake Reservoir Kit Comprising of HRC GP bike parts, hose 43503-NF4-000, bung 17370-419-700, clamp 43541-ND5-750, clip 95002-02120 as…

- Model

- BPAC-0001

- Quantity

- 20

Triple Clamp Set, CNC Black, RVF400 NC35

Triple Clamp Set, CNC Black, RVF400 NC35 These stylish, all aluminium triple clamps are a direct replacement for the notoriously…

- Model

- TYLY-1242

- Quantity

- 2

Clutch Lever CNC Black, NC29/ NC30/ NC35

Clutch Lever CNC Black, NC29/ NC30/ NC35 CNC machined out of solid billet. Dog legged lever for Honda 4 stroke…

- Model

- LEVC-9012

- Quantity

- 2

Clutch Lever CNC Black, NSR250, CBR250RR

Clutch Lever CNC Black, NSR250, CBR250RR CNC machined out of solid billet. Straight lever for NSR250 (MC18, MC21, MC28), CBR250RR…

- Model

- LEVC-9011

- Quantity

- 2

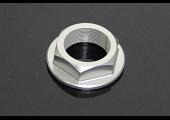

Top Triple Clamp Nut (M24x1)

Top Triple Clamp Nut (M24x1) Top clamp nut machined from 6061 T6 aluminium. Light weight and good looking. Clear…

- Model

- TYLY-0027

- Quantity

- 25

Wheel, Front. Aluminium Spacer kit NSR250 MC21/28 & VFR400R NC30

Wheel, Front. Aluminium Spacer kit NSR250 MC21/28 & VFR400R NC30 Replace the heavy steel front wheel spacers and wheel…

- Model

- TPER-0024

- Quantity

- 16

0 items