TYGA NSR150SP Repsol

TYGA NSR150SP Repsol

February 2010

Like all good stories, this one began when a few friends were having a chat over a beer or two. We all had Honda 150s and it seemed like a good idea (at the time) to go touring on them at the weekend. We decided on a nice trip to Khao Yai National Park and Khorat. The only problem was, my bike was a CBR150 and not an NSR150, and being a hard core two stroke enthusiast this was going to be humiliating for me. Luckily, I spotted a stock but scruffy example for sale at a used car lot on my way to lunch and was able to make a quick purchase, load the bike in the truck and still be back to the office in time before my food was cold! A quick service that evening, no gremlins found and the bike performed perfectly at the weekend. In fact, all three NSRs did the 36 hour 700km trip without incident. The only bike that played up was the CBR which I had lent to another friend but ended up riding most of the trip because he couldn't keep it on the boil. Anyway, enough of the intro, now this bike was in the fold, it needed some TLC and that is exactly what it got.

Due to lack of time more than anything else, we didn't give the NSR a full restoration. The bike did receive a very thorough clean and inspection. Due to the relatively cheap price of the parts on this Thai made bike, it made a lot of sense to replace rather than repair or repaint. By the time we had completed our Honda shopping list, we had replaced every painted panel and the fuel tank, the screen, sidestand, mirrors, air ducts, headlight, fairing stay, seat and host of fasteners to freshen up the NSR aesthetics. On the mechanical side, we confined ourselves to service parts. The engine has done a high mileage but proved its reliability and performance so was left alone for now. The parts arrived in dribs and drabs from Honda so it gradually evolved rather than was quickly transformed. The panels are provided painted but you need to apply the stickers yourself which is an acquired skill and test of patience. Use of heat gun/hair dryer, soapy water and credit card help but I don't think it is my forte. The panels looked great until the next day when some creases and bubbles managed to magically appear. Anyway, it is not a disaster and a massive improvement on the panels which the bike was wearing before.

Apart from the shopping list to Honda, we made a shopping list to ourselves which included products that didn't exist at the time. We installed a prototype stainless chamber which we will put in production soon and carbon/Kevlar silencer as well as carbon reeds and a custom carburettor with pod filter, which Matt modified to use the autolube system. The stock 150SP cylinder head is designed more for Bangkok's traffic filled streets than the open road, so we felt the need to fit a VHM head too. We also fitted one of our new style single seat units, a step kit and Matt designed a top triple clamp and key holder to suit. There are a few other TYGA products added such as the carbon heel guard, filler cap cover and brake reservoir. The front master cylinder was junked for a 14 mm. NC35 one and we fitted braided hoses.

The rear end needed some tidying up. The Pro Arm is a great feature of the SP but looks cluttered on the stock bike. We junked the chain guard for a modified R1 carbon one and the biggest change, of course, is the rear wheel. This was liberated from an NC35 and being of 4.5 inch width was initially a struggle to get it to fit. With a mixture of MC28 hub parts and sprocket and the original 150 brake and holder, we were able to make the modifications without resorting to offsetting the wheel or machining parts. The chain runs true, but we did need to fit a 140 section rear tyre to get clearance and we selected this particular tyre with a high profile to raise the rear end and give it a chunky feel. While restoring the bike we discovered that the rear spring on the stock suspension had actually cracked all the way through, (nice thought considering all the touring it had just done) and although stock units are available, we opted for a YSS unit with remote gas reservoir. The gas reservoir is a bit tricky to find a home for, but it fits in crosswise above the swing arm pivot with the use of a large hose clamp and some foam rubber.

Riding the bike now is a totally different experience to the bike I once toured on. The bike feels much more lively and lighter than before, thanks in no small part to the exhaust system. The brakes now actually work and inspire confidence when hauling the bike up quickly. The rear end feels higher and more planted but not radically different from before. The bike loves to be thrashed and it is difficult to control the urge to rev out the little 150 in every gear. Partly this is due to the limited power available, but also because the way the top end rush invites you to open it up. It isn't going to impress any superbike fanatics (or any noise abatement advocates) but riding the NSR150 is a very pure two stroke experience which evokes the senses, is very involving, and makes you feel like you are on a mission whether it be a quick ride to buy some milk or a tour in the national park.

Set, Exhaust Chamber, Stainless Steel, NSR150SP

Set, Exhaust Chamber, Stainless Steel, NSR150SP The TYGA Performance NSR150 SP pipe is just what is needed to unleash the…

- Model

- EXCS-0024

- Quantity

- 13

Silencer, Carbon, Two Stroke, Assy.

Silencer, Carbon, Two Stroke, Assy. This high quality lightweight (0.47 kg) silencer is made from CNC machined end caps joined by…

- Model

- EXSL-0003

- Quantity

- 100+

Chain Guard, Carbon, 2004-8 Yamaha R1

Chain Guard, Carbon, 2004-8 Yamaha R1 Same shape as stock. To be used with our R1 carbon hugger BPCH-7002.…

- Model

- BPCX-7002

- Quantity

- 3

Carbon Tank Filler Cap Cover Honda

Carbon Tank Filler Cap Cover Honda Carbon Tank Filler cap Cover. Fits most Honda sports bikes including: …

- Model

- BPCC-0002

- Quantity

- 5

Top Triple Clamp Set, CNC Silver, NSR150SP

CNC machined top triple clamp with detachable ignition switch/lock holder for your NSR150SP.Designed and machined in house by TYGA, as…

- Model

- TYLY-0051

- Quantity

- 12

Heel Guard, Right Only, Carbon

Heel Guard, Right Only, Carbon Right side carbon fibre heel guard. It can be fitted to many other models, being suitable for…

- Model

- BPCC-9010R

- Quantity

- 100+

HRC Brake Reservoir Kit

HRC Brake Reservoir Kit Comprising of HRC GP bike parts, hose 43503-NF4-000, bung 17370-419-700, clamp 43541-ND5-750, clip 95002-02120 as…

- Model

- BPAC-0001

- Quantity

- 20

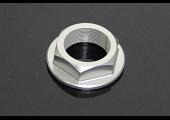

Top Triple Clamp Nut (M24x1)

Top Triple Clamp Nut (M24x1) Top clamp nut machined from 6061 T6 aluminium. Light weight and good looking. Clear…

- Model

- TYLY-0027

- Quantity

- 25

Screen Clear, NSR150SP OEM Honda

Screen Clear, NSR150SP OEM Honda OEM Honda Part. Exact same screen as original…

- Model

- 64110-KW6-840

- Quantity

- 3

Fairing, Inner V, NSR150SP, (Type 2, Repsol)

Fairing, Inner V, NSR150SP, (Type 2, Repsol) This is a genuine Honda OEM part. It is supplied painted but without…

- Model

- 64350-KW6-840ZB

- Quantity

- 1

Fairing, Lower Left, NSR150SP, (Type 2, Repsol)

Fairing, Lower Left, NSR150SP, (Type 2, Repsol) This is a genuine Honda OEM part. It is supplied painted but without…

- Model

- 64320-KW6-840ZB

- Quantity

- 2

Fairing, Lower Right, NSR150SP, (Type 2, Repsol)

Fairing, Lower Right, NSR150SP, (Type 2, Repsol) This is a genuine Honda OEM part. It is supplied painted but without…

- Model

- 64310-KW6-840ZB

- Quantity

- 2

Fairing, Mid Left, NSR150SP, (Type 2, Repsol)

Fairing, Mid Left, NSR150SP, (Type 2, Repsol) This is a genuine Honda OEM part. It is supplied painted but without…

- Model

- 64405-KW6-840ZB

- Quantity

- 1

Fairing, Mid Right, NSR150SP, (Type 2, Repsol)

Fairing, Mid Right, NSR150SP, (Type 2, Repsol) This is a genuine Honda OEM part. It is supplied painted but without…

- Model

- 64305-KW6-840ZB

- Quantity

- 1

Front Fender, NSR150SP, (Type 2, Repsol)

Front Fender, NSR150SP, (Type 2, Repsol) This is a genuine Honda OEM part. It is supplied painted but without stickers…

- Model

- 61100-KW6-840ZB

- Quantity

- 2

0 items

01tn.jpg)