Honda VFR400R NC30 Restoration

Honda VFR400R NC30 Restoration

November 2022

Text and Photos by Paul Pearmain and Matt Patterson © TYGA-Performance.

Shintoists believe that everything has a spirit called a kami, people, animals and even inanimate objects; presumably even beat up NC30s. Personally speaking, I am not particularly religious or superstitious but I can be sentimental when it comes to motorcycles and hate parting them out if there is any hope of saving them. This is the story about a very sick NC30 which nearly ended up on the scrap heap like so many others, however due to good fortune, hard work, and a tidy helping of TYGA Performance products instead, it was restored to the bike you see here on this page.

This particular VFR I acquired in 2008 and it started life as a Japanese spec TYPE 4. It was imported to Thailand many years ago in original but slightly damaged condition as was commonplace during that period. To tell you the truth, I wasn’t really in the market for an NC30 but a friend offered it to me for a very cheap price. Like so many of us bike collectors, it is hard to say no to a bike when you see such a good deal. However, as you bike addicts understand what it is like for me, I needed a good reason to justify the purchase. ‘I know’, I thought ‘ I’ll use it to practice clay modeling’.

Now that might have made sense to me at the time but the problem is that I am not really cut out for such patient and precise work. I’m a bit more of a ‘broad strokes’ kind of guy. Compounding my frustrations at becoming a bike designer was the tropical climate making the clay way too soft to shape. The final straw came when the mice moved in and I eventually admitted defeat and resumed my usual supervisory and less hands-on tasks here at TYGA Performance.

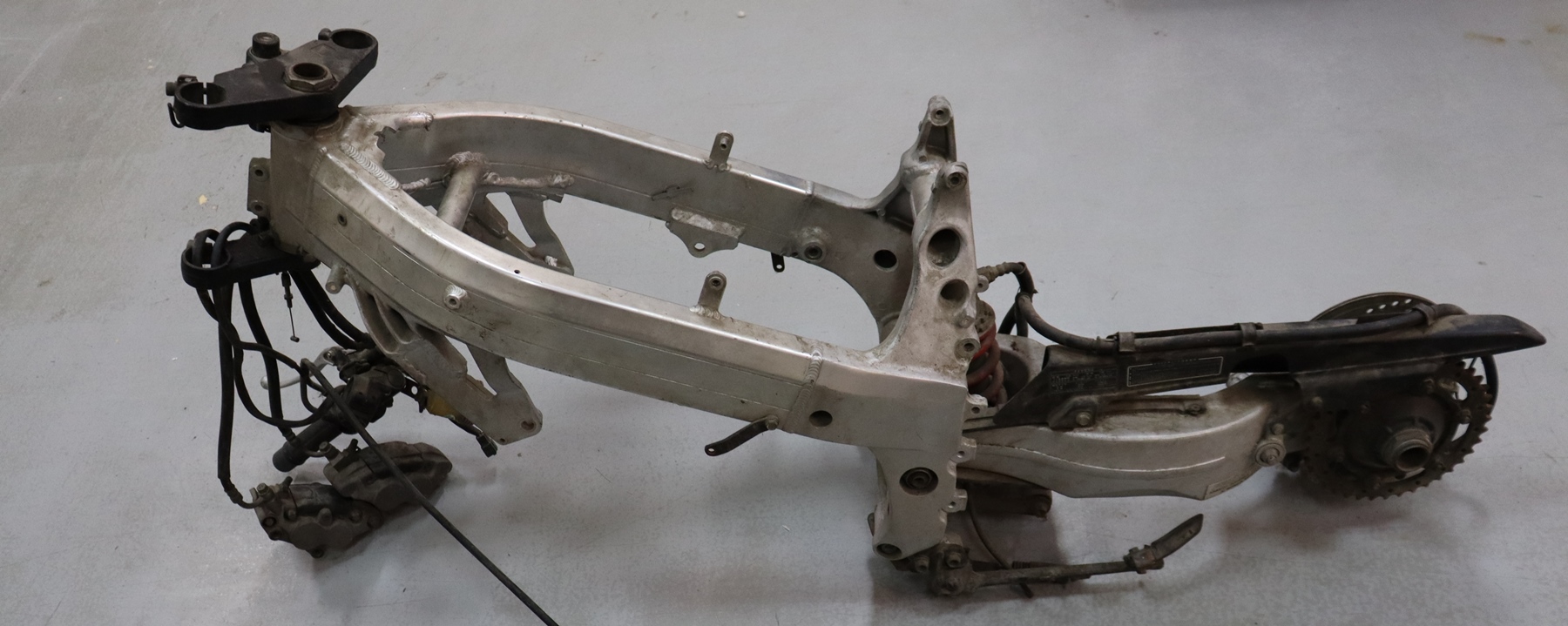

After I abandoned my efforts to be the next Tamburini, the bike just sat and festered under the weight of about 100kg of expensive imported Japanese modelling clay and mice poo. The high Sulphur content in the clay ate away at the engine coatings, and the mice poo caused its own issues as we will see later. Despite its poor condition, we found a new use for the NC30. It became a jig for test fitting everything from fuel tanks to upper stays to sub frames. The down side to this reprieve was that with every test fit, components were gradually removed for ease of access and the bike ended up being left out in the weather for no better reason than it was almost worthless and a waste of storage space. What had started out as one of the finest machines that has ever come out of Hamamatsu, had become almost unrecognizable but there was still some hope. The kami was still present.

It can take a lot to get a project like this started. For the NC30, there were actually a few things. Firstly, due to the proximity of the bike from where we take coffee, it was in plain view on a daily basis. It’s gradual deterioration became a constant reminder for us to do something about its plight. Then the next impetus came when we temporarily mounted our latest generation stock NC30 bodywork and composite fuel tank on it to check for fit and finish. The little V4 momentarily looked like a the high quality motorcycle it once was and for a flickering moment, there did indeed seem to be some hope. However, after the nice new bodywork was removed and the rust revealed itself again, any enthusiasm just as quickly evaporated.

The final push to get things started occurred when Glenn kindly bought me a brand new speedometer internal mechanism. He thought they were actually for the NC35 that we were working on at the time but, fortuitously for this bike at least, if not for the RVF, it was actually an NC30 component. Call it fate, but this is what got things eventually started!

Now one issue we had was that the registration had long ago expired and it would be a nightmare trying to get it renewed. The easiest solution was to find a cheap registered bike with a nice frame and do the switcharoo. Hopefully we could then cherry pick from the pile of parts and there would be enough good bits to make one tidy bike. Cherry pick is probably the wrong word. The registered bike which I bought, ran ok and I even went for a short test ride to make sure the wheels weren’t going to fall off it. Maybe I should have been a bit more thorough at looking inside the fairing too because along with all the usual shortcuts and bodges there were a few nasty surprises too. The wiring was a disaster and had all sorts of add-ons spliced in ranging from remote starting, to fans, to regulators, to alarms. It was junk. Luckily for us, the beaten up bodywork it was wearing would not be required for this project. The problem was that in installing the custom bodywork, the subframe, rear fender and even rider seat pad had all been hacked up beyond economical repair. Meter stay looked like it had been made out of a shelf bracket and the upper stay was bent and re-welded. The list of disasters went on. Handlebars were hand made out of aluminium bar, radiators bent, clogged and nasty, hoses swollen. Etc etc. You get the idea.

A suitable engine was however the major issue. The engine from the clay bike I was hoping would be usable but despite having carbs on it, when they were removed, you could see a lot of corrosion in the rear bank due to rust. I blame the mice wee! No problem, I thought; we can just use the registered bike’s engine. It ran great on the test ride. The only trouble was that when I bought that bike, I hadn’t noticed that it actually had an RVF engine which was a stupid novice mistake. We wanted to build a stock NC30 and an NC35 engine wouldn’t really cut it. Even painting it brown, I’d know it was wrong so we were two bikes into this project already and still no suitable engine.

Luckily, we know a good importer and we found a ‘fresh out of Japan’ engine. The good news was it was available and very cheap.

The bad news was the front engine mounts had both cracked off which is common on accident NC30s. We have the technology to weld them back on but after carefully making a jig and welding, Matt thought it would be a good idea to run some water through it under pressure just to be sure there were no leaks. The head failed with water dripping and squirting out of numerous tiny cracks we hadn’t noticed which were totally unrelated to the area that had been welded. Not wanting to have an engine that looked like an apprentice’s practice piece with beads of weld all over the place, we discarded this head and opted to use the front cylinder head from the mice toilet engine instead. Luckily the mice preferred to do their business in the rear bank and the front head was still relatively fresh.

That said, poor Matt ended up having to lap in the valves in this head. Next, having wisely removed and checked the rear cylinder on the ‘fresh out of Japan’ engine Matt found that the valves in this head needed lapping in too. This work was not really planned and took up time but definitely worth it (especially when it is someone else’s time, sorry!) “Better to be safe than sorry, but yes, it was a bit of a pain” - Matt

I should mention at this point, being a bike which was primarily stock, it shouldn’t require much engineering and initially, I was hoping not to bother Matt too much. This turned out not to be the case and as well as the engine woes, he had a complete carb rebuild to do too. The mice had permanently seized up the set on the clay bike and the registered bike’s carbs had stiff diaphragms that were reluctant to fully open the slides. We had a set of NC24 carbs in storage which Matt hoped would be willing to donate their organs to a good cause. The only issue was that the NC24 diaphragms were of a slightly different design. A little (very well informed) bird told us that actually this was a positive thing and the NC24 type was the type used on the HRC kit. All good then!

I have to say that I was pretty shocked at the state of the carbs. I'd have never guessed that "essence of rodent" could have caused so much damage. There's very few jobs that defeat me, but I have to say that after a week or so of soaking in various juices, I did just hold up my hands in surrender! - Matt

Forks were another disappointment. We had 2 pairs of forks from these bikes plus a few pairs in storage, and then while sniffing around the right places in Bangkok, I was offered a great deal on a frame, swing arm and fork set. Surely one of these sets would just require a quick oil change and be ready to go! As you are probably guessing with this story, it was never going to be that straight forward. When we started inspecting closely, all the legs were exhibiting one or more of the following issues; worn lowers, bent or rusty stanchions, crusty and corroded caps, worn adjusters etc so like everything else, in the end, it was case of taking the best from a bad bunch. Poor old Matt! He had to pull apart about 8 legs to get 2 good ones.

My life wasn’t much easier either. The aforementioned brand new speedo was great but both bikes clusters had the usual clutch adjuster scuff marks on the casing and it would be sacrilege, not to mention unconvincing, to use a dinged up case for a brand new mechanism. I hunted around in our store and dragged out 2 and half more sets. Between them all, and some new Honda bolts and rubber parts I had ordered, I managed to make a pretty clean set as well as a ‘spare set’ for some future project that might not mind a few ‘character’ marks.

This pattern of work was repeated with everything from filler caps (stealing the less scuffed centre of one to go on the ring of a prettier one), switch gear, swing arms, rear shocks and foot peg assemblies.

We found ourselves cleaning up duplicates and then taking the best components from the various parts we had at our disposal to make one nice one.

For the passenger pegs, we were seriously lacking original NC30 ones so I even resorted to using some MSX125 passenger pegs we had in storage.

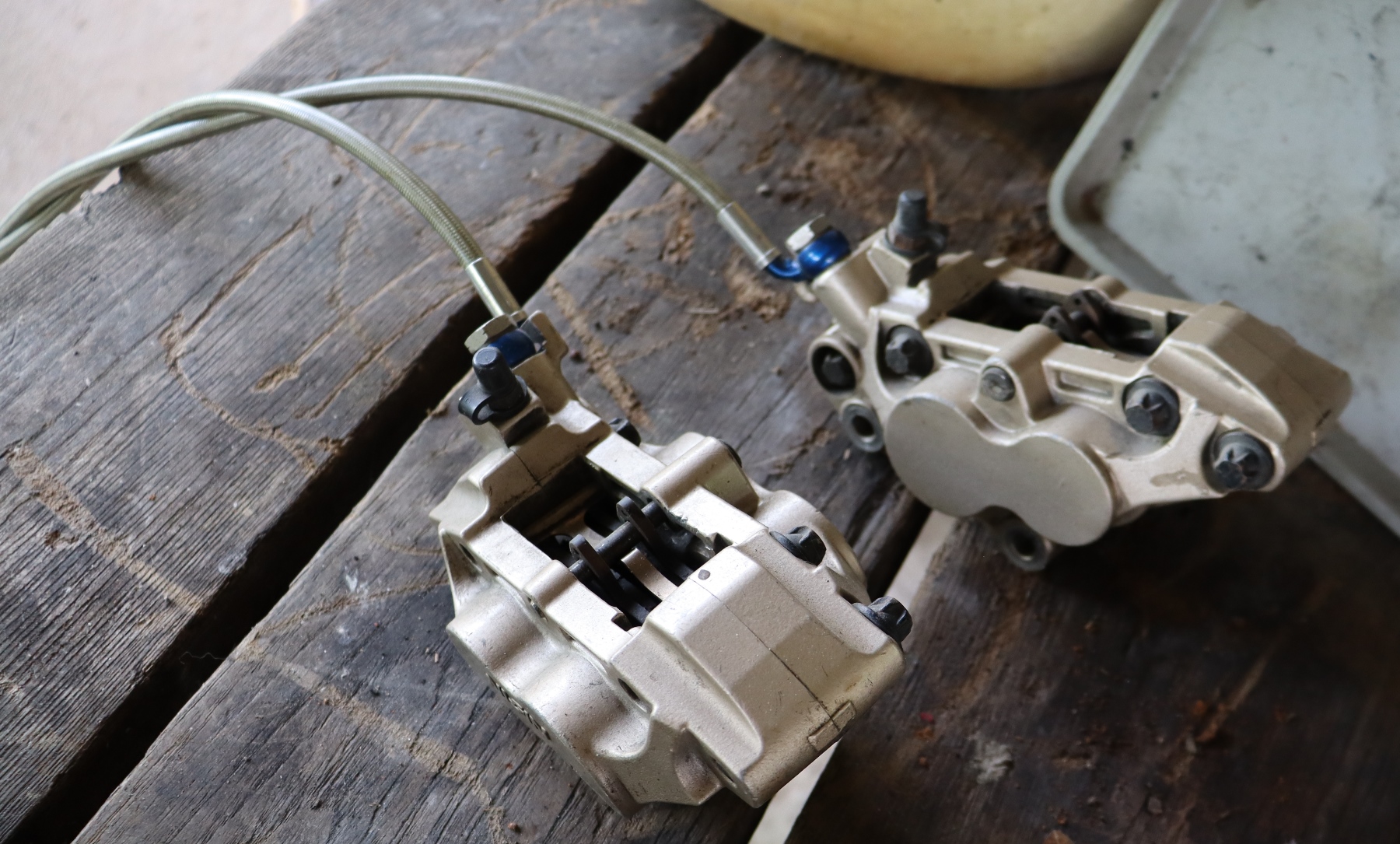

I bet nobody would have noticed that shortcut! Brake master cylinders were the same story. We rebuilt one and for some unknown reason it just didn’t want to work properly. We had several more master cylinders in storage so it was easier just to service another one and use that one instead. After all, its only money and another hour spent! The calipers, oh yes that was fun! They had been on the Force V4 project bike so I assumed they were all good to go. Wanting to make some progress with assembly, I foolishly installed them without servicing them first, only to find the brakes binding. So off they came again in order to clean the pistons. Now, I thought it was just because I have a mangled knuckle from being T boned off my CRF but I could not pull the pistons out of their holes. I pleaded disability and handed the job to Matt. I kid you not, it took him a full two hours! The seals had actually turned themselves inside out and locked solid. After Matt’s attention and new seals fitted, they are now like new. It was starting to seem like to build one bike we had done the work to restore two or three and in reality, this was not far from the truth. Over to Matt:

“On the forks, it was actually quite amusing on one leg. As hard as I tried, the thing would just not come apart. I had to very carefully get in there with my die grinder and tickle away at the seal intul I was able to eventually hook it out. I wouldn't have done it, but the stanchion was in great condition, so worth the extra attention. The brake calipers on any restoration we do always need a lot of TLC, but as Paul says, these fought courageously to the end. All the cripsy crystalized fluid was cleaned out and the bores given a quick hone. With new seals and cleaned up pistons they felt lovely.” - Matt

Like I said earlier, I am a broad strokes type of person and I’ll admit that not every nut and bolt was replaced. Heck, the engine was cleaned but apart from the rocker box covers, it wasn’t even painted. It still has some ‘honest’ scuffs on it. One thing I did want to get right was the bodywork mounting hardware because this bike was to be used in the launch of our TYPE 1 painted sets. It was a good opportunity to see exactly what we need to provide and what could be retained from a standard bike. We therefore ordered well over a thousand dollars- worth of nuts and bolts including suspension and engine mounts. We also recoated the ones we removed from the bikes so any that were not available new, we could use old and not hold up things. The advantage of this approach is we end up with a net gain in our bins of general nuts and bolts for the next project.

I should really keep a stop watch to see how many hours I spend rummaging through bins to find used parts. Why is it when I am looking for a project’s parts I can’t find them anywhere but when I am looking for the parts for the next project, out they pop? There were lots of NC35 parts all over the place but none 6 months ago when I needed them. Now when I need them, a lot of the NC30 parts I have been keeping for years have snuck off and hidden themselves. I knew I had a few things stashed away such as fork front fender rings and they were easy to find but the side bushes to hold the lower cowling, we used to have lots. In the end, I managed to find one. From that one, Matt carefully measured it up and made us a duplicate so now we have a new product.

Passenger seat lock and mechanism was another thing I couldn’t find. In the end I gave up looking and out sourced this along with the rubber shrouds for the seat cowling side ducts. Of course the seat mechanism revealed itself attached to a subframe a few days after this project was finished…

It might sound like a lot of complaining, and I’d be lying if I said we didn’t moan more than a bit. However, it helps when there are a few of you to get it off your chest. Having a team with different skills and resources and a mountain of spares is helpful too. These days, the online community is invaluable for advice and google is great for identifying bolts or small components so in some ways it has never been easier to do this type of project. The thing is to break each job down into manageable chunks and then be prepared to temporarily switch from one area to another when progress can’t be made on one thing. We keep a white board next to the work area so it is easy to add items before they are forgotten and also very rewarding when items are removed from the board as they are completed. Building a bike is much like anything else which is challenging. It is mostly in the mind!

As I alluded to earlier, the build is really to show case our stock shaped bodywork all painted up to entice visitors to do the right thing and choose TYGA over something inferior made in a country not too far from here. The other thing we wanted to show was that by choosing our complete sets of bodywork, even including the fuel tank in some cases, works out similar in cost to just painting panels in many countries.

There is a good argument to be made to put the stock plastic in storage, even if it a bit scuffed and install a shiny new TYGA set to use for now. Then, when the time comes to sell your bike you can be one of those responsible sellers who we all want to buy from who says they have the original fairings in storage to sell with the bike.

As well as the bodywork, as is often the case when we do a project, other new products come to mind. For the NC30, we already had the meter and upper stay so we decided to make the side stays and the bushes. Our bike was missing headlight rubber shrouds, so we now produce those too.

Same for the chainslider and the top taillight bracket. We have a stock subframe now with the twin seat but if we were to install the single seat version, our TYGA subframe would save weight and trouble restoring the bent one we have on it now. Of course, if we gave ourselves a free rein instead of trying to restore a stock looking bike, the exhaust would be gone in an instant and probably the foot controls too. Everybody has an opinion on what constitutes a perfect NC30. Ergonomically, our RC211V and GP-T kit makes sense especially for racing. Purists on the other hand want everything looking as it came out of the factory. Others prefer the odd upgrade in performance and reduction in weight. In any case, I think we now have all bases covered here at TYGA. Over to Matt:

‘Paul briefly mentions the NC30 standard exhaust here. What he didn't say was that we did actually have to chop off a couple of corroded and cracked slip joints and make new ones, and then spend several hours cutting out scratches and buffing it. Thankfully the last part was the job of Khun Ree. He'd had great practice doing the NC35 pipe and again, did a fantastic job with the NC30 pipe.” - Matt

I’ve gone on for way too long so if you’ve skipped all this text, nothing missed really, just a lot of pain and problems. Just enjoy the photos. As they say, a picture is worth a thousand words and I’ve got several pictures worth already typed out. I’d just like to end with this. I’m peering over my computer and looking at the beautiful finished bike sitting on its service stand, I can sense the ‘Kami’ of at least two NC30s and get the impression that they are thanking me for saving them. After all that hard work and suffering what better reward could you ask for?

December 2022

Below some photos of the very same NC30 but now fitted with our BPFT-0121type1 single seat cowl to give that RC30 look

Fuel Tank, GRP, VFR400R NC30, Unpainted

Fuel Tank, GRP, VFR400R NC30, Unpainted Top quality reproduction of the steel NC30 fuel tank in GRP. This…

- Model

- BPFG-0005

- Quantity

- 4

Chain Slider (set), VFR400R NC30

Chain Slider (set), RVF400 NC35 Replaces Honda part number 52170-MR8-003 Uses two black Delrin sliders that screw…

- Model

- TYLY-0299

- Quantity

- 11

Rubber Shield, Head Light, Pair, NC30, NC29, MC22

Rubber Shield, Head Light, Pair, NC30 Reproduction part and replaces Honda part number: 33106-MR8-000 Also fits: Honda CBR400RR…

- Model

- BPAC-0016

- Quantity

- 13

Seal Gap, Headlight, Pair, 40cm

Seal Gap, Headlight, Pair, 40cm Two pices of square section foam that are glued around the…

- Model

- BPAC-0017

- Quantity

- 5

Side Mount, Lower Cowl, NC30

Side Mount, Lower Cowl, NC30 Reproduction of Honda OEM part number: 64517-MR8-000…

- Model

- BPSY-0323

- Quantity

- 100+

Stay, Standard, Side Cowl, Left, NC30

Stay, Standard, Side Cowl, Left, NC30 Reproduction of Honda OEM part number: 64520-MR8-000 …

- Model

- BPSY-0325L

- Quantity

- 18

Stay, Standard, Side Cowl, Right, NC30

Stay, Standard, Side Cowl, Right, NC30 Reproduction of Honda OEM part number: 64510-MR8-000 …

- Model

- BPSY-0325R

- Quantity

- 30

Set, Windscreen Molding, and Clips

Set, Windscreen Molding, and Clips This product can be used on windscreens which have a rubber molding…

- Model

- BPAC-0015

- Quantity

- 33

Frame In-Fill Panels, Pair, GRP, NC30

Frame In-Fill Panels, Pair, GRP, NC30 GRP frame in-fill panels in satin black finish for NC30. Ideal for…

- Model

- BPFC-7417

- Quantity

- 1

Front Fender, GRP, NC23,NC29, NC30, Stock Shape

Front Fender, GRP, NC23,NC29, NC30, Stock Shape Top quality GRP reproduction of the stock OEM Honda front fender (weight…

- Model

- BPFF-0005

- Quantity

- 5

Lower Cowling, GRP, NC30 Stock Shape

Lower Cowling, GRP, NC30 Stock Shape Street one piece lower cowling with open bottom as stock. Direct replacement for OEM…

- Model

- BPFL-0003B

- Quantity

- 2

Passenger Seat Cover, GRP, NC30, Stock Shape, Assy.

This passenger seat cover replaces the passenger seat pad on the NC30. Simply remove the original seat pad and replace…

- Model

- BPFX-0021

- Quantity

- 1

Seat Cowling, GRP, NC30, Twin, Stock Shape, Street

Seat Cowling (GRP), NC30, Twin, Stock Shape, Street Stock shape seat cowling with taillight holes. Twin seat, direct…

- Model

- BPFT-0021

- Quantity

- 1

Upper Cowling, Street, GRP, NC30, Stock Shape, Assy.

Upper Cowling, Street, GRP, NC30, Stock Shape, Assy. Stock shape, replaces the front upper as well as the two side…

- Model

- BPFU-0021

- Quantity

- 2

Upper Stay, Stock Shape, NC30

Upper Stay, Stock Shape, NC30 Upper /Mirror Stay for NC30. Similar to stock item. Replace…

- Model

- TYLY-0290

- Quantity

- 2

Bolt, Front Brake Rotor Mounting

Bolt, Front Brake Rotor Mounting Front brake mounting bolt. Bolt, M6 thread with a dome head and 6 mm. Allen…

- Model

- 90106-KGH-600

- Quantity

- 24

Gasket, Exhaust

Gasket, Exhaust Compatible with: With NC30/35 exhaust systems including TYGA systems: EXPS-0002 Set, Pipe, Full Race System NC30-35 (No Silencer) …

- Model

- 18291-MN5-650

- Quantity

- 100+

Wheel Bearing Set, Front MC18/21/28

Wheel Bearing Set, Front MC18/21/28 Replacement front wheel bearing. OEM quality assured 2x Bearings included…

- Model

- TYPP-0009

- Quantity

- 13

Front Brake Light Switch, Assy.

Front Brake Light Switch, Assy. OEM Honda front brake light switch Alternative to 35340-KV3-700 and Compatibile with…

- Model

- 35340-MGS-D31

- Quantity

- 5

Fork Seal Kit, 41 mm.

Fork Seal Kit, 41 mm. Fork Seal Kit, for Honda 41 mm. forks. Important! This product includes, two…

- Model

- 51490-MN8-305

- Quantity

- 34

TYGA Bike Dust Cover, Red/Black, Force V4 VFR400R

TYGA Bike Dust Cover, Red/Black, Force V4 VFR400R This cover is handmade from 100% breathable polyester and ideal for…

- Model

- TMER-0169

- Quantity

- 7