Kawasaki KRR150ZX

KAWASAKI KRR150ZX

March, 2022

Text and Photos by Paul Pearmain and Matt Patterson, © TYGA-Performance

When you think of Kawasaki Ninjas, you probably conjure up images of powerful inline four cylinder ZX-Rs or possibly even include small capacity four stroke twins. Unless you hail from Indonesia, Malaysia or nearby, then it is surreal experience to witness a bright green Ninja simultaneously disappearing into cloud of its own smoke while at the same time emitting the unmistakable ring-a ding ding of a two stroke.

Welcome to the KRR150ZX, AKA the Ninja RR, KRR ZXR150 and all the other various names it received depending on the market it was sold in.

As well as a confusing nomenclature, the model years are somewhat confusing. It appears to have been released around 2000 in Thailand and was still being sold in Indonesia up to a few years ago. You’d have to be a real ZX anorak to work it all out and there’s not space here, so let’s just get on with the story of this particular Ninja.

The bike shown here had a quite a typical life in one regard in that it was one of 16 bikes acquired by Castrol Thailand Technology Center.

The way this was done was to distribute the Kawasaki’s to various lucky motorcycle riders who were then instructed to ride them as everyday bikes and use and abuse them as they would their own bike. The motors were stripped before and after each oil test and checked for wear and tear to see how the various oils had performed.

At the end of the program, the bikes were returned to the business which was testing the bikes for the oil company. On the one hand, the bikes were fortunate as they had plenty of engine maintenance but conversely, if ours was anything to go by, they weren’t shown much (if any) love. To be fair, we didn’t purchase ours until many years after this program had been carried out and two strokes had mostly been forgotten in Thailand. I think it was around 2008 if I remember correctly. Fashion had changed and ours was the last of the development bikes remaining and was abandoned, unwanted and untouched in the back of the workshop.

Colin the business owner was and is very astute and knew how to pull the right strings to get us to buy it. Looking back, I think we might have paid a little too much but then again, looking forward to what they are worth now, we practically stole it. All things considered, we were grateful that it didn’t have any accident damage and with the exception of a few bodywork fasteners was complete when we took over custodianship.

The trouble was, as is often the case with us motorcycle enthusiasts, we bought it on impulse but didn’t really have the time or inclination to restore or modify it. Years went by and it got even dustier and looked even more forlorn as parts were removed for testing TYGA steps and a few other components. Luckily, even though it is an affordable mass produced bike, the build quality is pretty good and it was always stored in a dry, if not particularly clean environment. Being a greasy oily two stroke helped preserve components and I don’t think it had really been properly washed since it was new; certainly not for the last 15 years.

As we all know, two strokes have become more popular and even ‘lowly’ 150s are sought after and valued nowadays. There is a huge fan base for the Kawa 150s in Thailand with gatherings and bike meets with hundreds of bikes. Similarly, in other parts of South East Asia such as Indonesia and Malaysia, where it had never really gone out of favour (or production), we started to see a boost in sales of TYGA Performance products for the 150. Interest really started picking up a the beginning of last year so we decided to put more focus on the Kawa and finally invest some time and resources. The end result is the bike you see here today.

Work began in June 2021 when we started pulling the Ninja apart. As you can see from the photos, it was not a disaster but had seen better days. As we dug into it, it began as a dusty job and ended up as an oily one. I took these photos to help with reassembly and forgot to change the setting so many are a bit blurred. I didn’t really want to inflict this filth on my phone and just getting the job done was my objective. Nevertheless, I did take a few pics to help with re assembly some of which are included here.

I suppose, as is normally the case in these write ups, it is incumbent upon me to provide some sort of goal or theme to this build. Obviously here at TYGA Performance where we like to modify things, a meticulous factory restoration was never going to happen. With the myriad of aftermarket parts readily available locally, it was tempting to ‘deng’ (Thai for decorate) it with some trick swing arms, radiators and even wheels but we managed to control ourselves and focus the build and our followers’ attention on the TYGA Performance components and products we offer for this bike. As well as the detail, we had to settle on an overall appearance and colour scheme. I spent an evening with various polishes and waxes on the original paintwork with the hope that they could be brought but to their former glory.

This was not to be due to too many scratches and blemishes. I can’t say I was disappointed because now it gave me an excuse to change to a nice fresh Ninja green and we chose this Indonesian market scheme that was never offered here in Thailand.

Seeing as we were now diverging from the original colours, we then decided to make a few tweaks to the factory version selecting black for the frame and swing arm and green wheels to match the body. The idea was that the green and black would complement the bright CNC aluminium and carbon parts that were in development at that time which we earmarked to be showcased on this bike. That was the plan…

So one thing to remember when doing a project is to do as much research on things before you start so you know where to source everything and keep really good records of what you need and what is ordered etc. This makes the process run smoothly which in turn lowers stress and makes the build more fun. I suppose we have got a bit cocky over the years, having built several Thai domestic Hondas We thought this one would be a simple case of going through the Kawasaki parts list and ordering from Kawa Thailand and it would all appear in a nice big box the next week. We were rudely mistaken. First thing to note is even though this model was about the last two stroke to be introduced to the Thai market, Kawa have pretty much stopped supporting it. Our wish list was thrown back with more NLAs than prices.

While we are on the subject of prices, they were all over the place. Some plastic panels such as the rear fender very reasonable but other components ludicrously expensive, by any comparison, let alone for a bike that Kawasaki were able to push out the door for under around 2000 dollars new. We didn’t really have a budget (good job or we would have been fired) but even so, there is a psychological limit on how much we wanted to spend on a mass produced 150cc domestic model bike. So we consoled ourselves by noting we had obtained it for well under the current market value; so we had some wriggle room there. This was quickly used up. For the unavailable parts on our list, we looked further afield; online vendors, from our distributors and customers in Indonesia, Singapore and Malaysia (big thanks to everybody!) and a local shop who very inconveniently told us they couldn’t source many parts but then consistently delivered said parts as soon as we had already sourced elsewhere!

With all this confusion, I must admit, my excel spreadsheets had more and more tabs added in a vain attempt to make order of the chaos. I got more and more confused and in the end I just had to pause from ordering and give the parts a month or two to all arrive or not and take stock (literally) of the situation. Luckily we had almost everything (and double of lot more than I care to admit). The final things to show up were the brake caliper pistons which I couldn’t find at a reasonable price. Eventually, after 7 months of looking in January this year, a kind customer donated them. And that was the finishing touch.

There is always a silver lining when things don’t go to plan and in this case, it meant we had more and more time to make products. This enable us to tick off quite a lot in the ‘to do’ list.

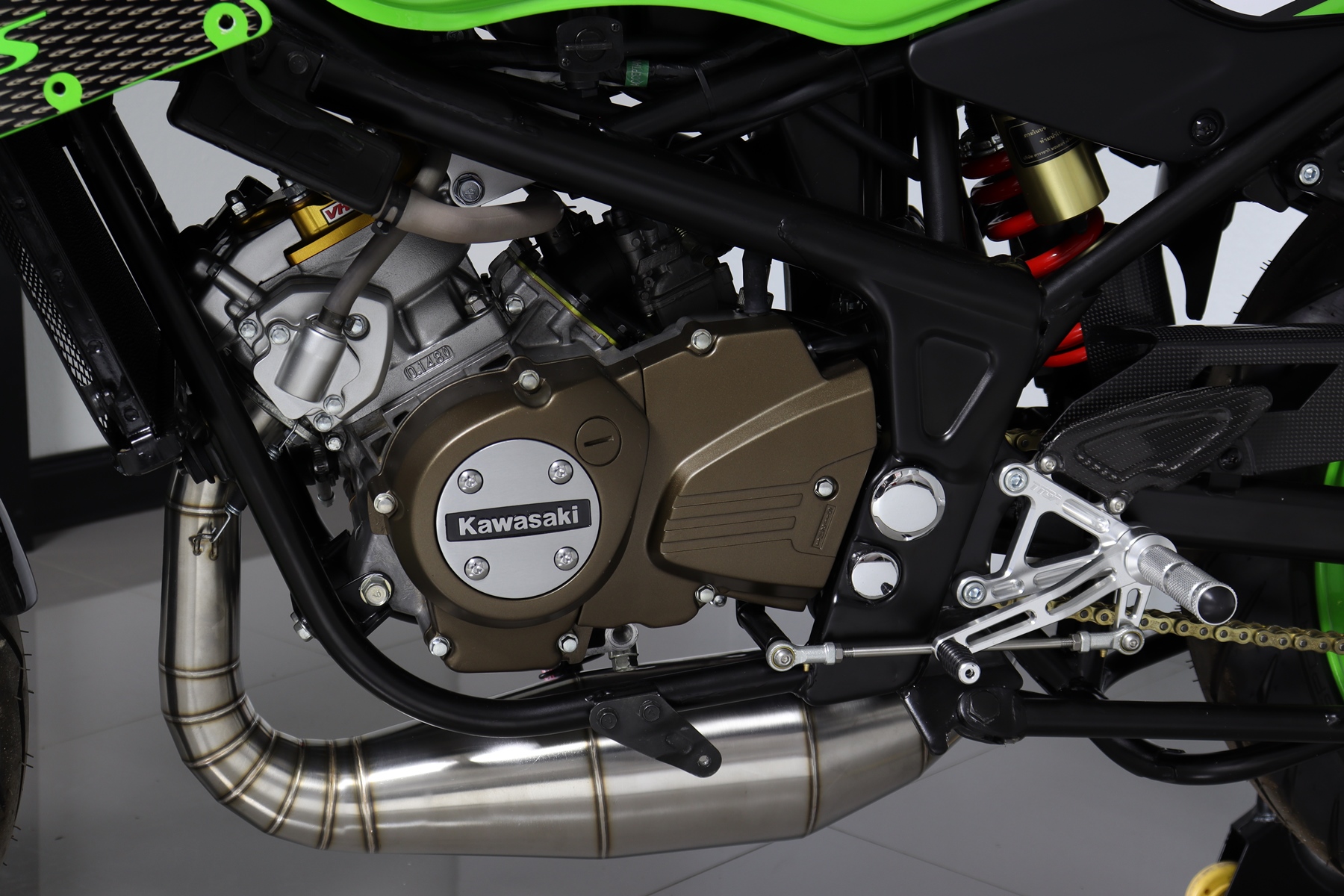

By August 2021, Pong had finished painting the frame, wheels and engine covers and other small parts.

This gave me the opportunity to do the fun part of building up the rolling chassis. The newly painted panels and tank weren’t going to be ready for a while At this stage it didn’t matter. Matt still had the engine to build. In preparation for that, we had gone through the parts list, managed to source as many bearings, seals, gaskets, major mechanical components for the crank rebuild as possible. Matt had kept a cylinder for a decade or more just waiting for this opportunity to put it to use. So with the original engine components cleaned up, the various cases painted and the new service parts ready to go in. It was time to rebuild the engine. Over to you Matt.

Thanks…..

As far as ‘been parked for over 10+ years” engines go, this one didn‘t look particularly bad. A quick scrub while fully assembled got most of the crud off and was able to start pulling it to bits without having to wash my hands every five minutes.

I’m not particularly experienced with KRR150 engines, so for once I actually started separating the components are I removed them so that I’d have a rough idea of how to put it back together. But I quickly got bored of that and just threw everything into a box and figured that I’d work it out later.

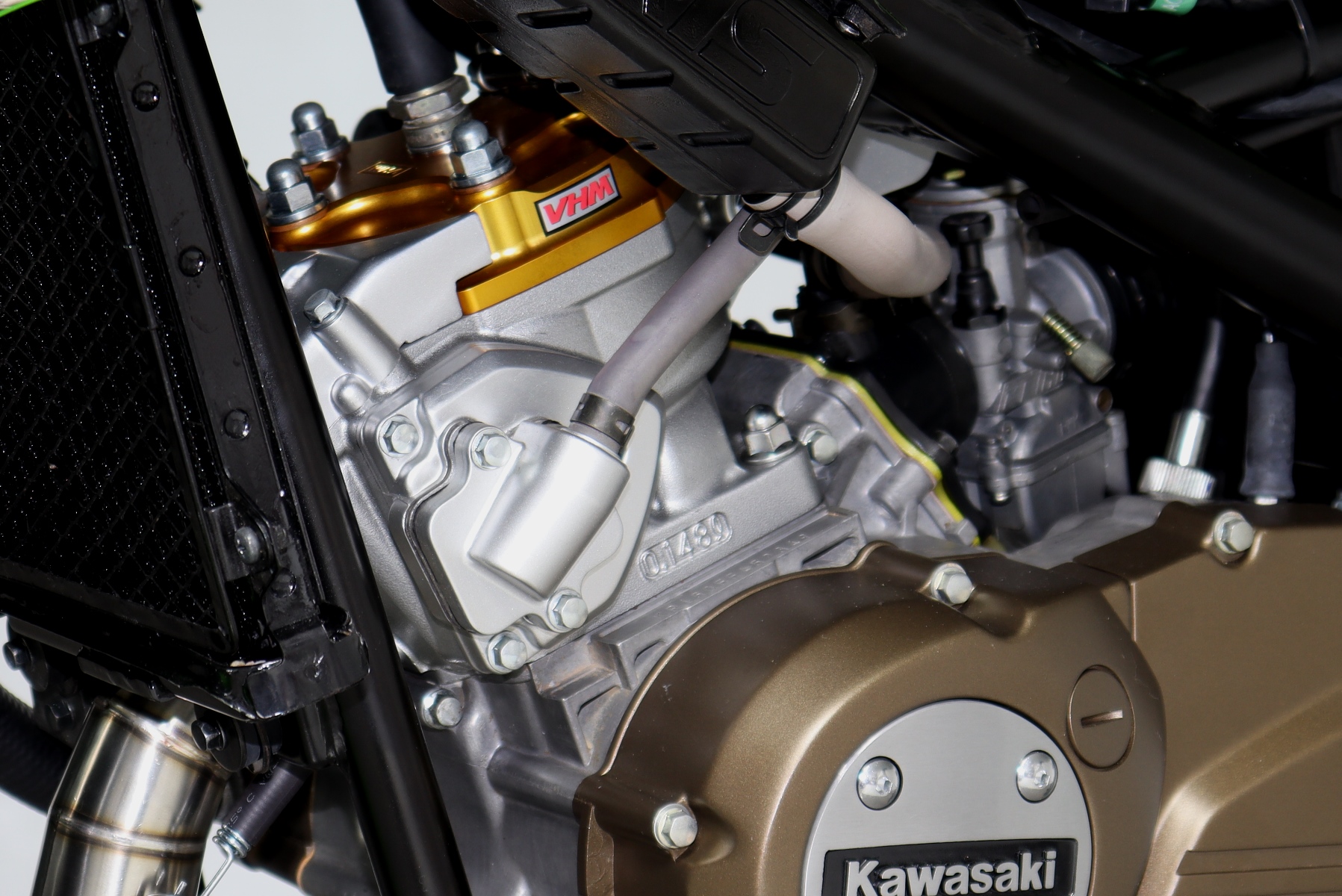

The top end was in reasonable condition considering the lack of love it’d been shown, but that wasn’t a big thing as I had a brand new cylinder and cylinder head hiding in my magic cupboard, so I wasn’t that concerned. And I’d planned to stick a VHM head on it anyway.

A quick wobble of the con rod proved that yes, the crank would need rebuilding and thankfully after a lot of trawling Paul had managed to source an OEM crank rebuild kit.

As usual, removing the water pump cover revealed a gooey mess. Not as bad as some I’ve seen recently (the Honda LS125 springs to mind here) but it would definitely need a bit of attention to get it back to (something) like new condition.

The rest of the disassembly went without much to report. The clutch was all good, as was the transmission. Really good in fact, and a tribute to that well known oil company that kept the spinny bits lubricated.

I’ll spare you all the details of cleaning the parts. Not a particularly exciting event, but reasonably satisfying none the less.

Now, It’s almost impossible for me to rebuild an engine without modifying at least one thing, and in the case of the KRR I wanted to give it a little clean up here and there as there were a few lumps and bumps in the cases that definitely shouldn’t be there.

I started with the cylinder. Now this was a Malaysian spec cylinder (code: #1855), whereas the cylinder that came on the bike was an #1878 marked cylinder. The differences were many, with the most obvious being that the #1855 used O-rings to seal the cylinder head whereas the #1878 used a regular head gasket. The porting was also quite different. I opted to use the #1855 cylinder and set about just cleaning up the port windows. Not a tune, just a tickle.

I then moved onto the cases, and here’s where I got the biggest surprise. Upon offering up the reed valve, not only did the top middle reed petal open up and fire straight into the rear piston support of the cylinder, but the two lower, outer petals were banging into lumps in the casting of the cases long before they were fully open. Now I don’t really know if that was engineered into the design, but it certainly wasn’t in my design, so out with the grinder to remove these offending nodules, and put a nice radius on everything else while I was there.

With the minimal mods done and another cleaning session, assembly went smoothly, right up until it was time to fit the VHM head.

We’d contacted VHM and they’d quickly supplied one of their fabulous gold anodized heads which arrived in no time at all. Upon offering it up, it was for the #1878 cylinder, so had O-ring grooves……Aaaaaarrrrggghhhh!!!

I then spent an afternoon with every combo I could come up with, measuring piston heights, squish clearances and head volumes so that I could get exactly what I needed from VHM, who, being the fantastic company that they are, quickly made all the parts to my spec and they were in my hands within just a few days. So in no time at all the engine was fully crewed together and sitting on the floor next to the bike ready for installation.

Throwing the engine in an old tatty bike is pretty easy, but when the frame is freshly painted and everything is 100% scratch and blemish free it’s a bit of a worry. But with cunning rag placement and a steady hands, Paul and I got the engine in without a chip or a scratch (which is probably a first LOL!)

Wiring, hoses and cables were a bit tricky thanks to Paul’s rather blurred pictures as he mentions earlier, but I think we got it pretty close to how it should be.

Another gem that I’d been hiding in the cupboard was a Keihin PWK28 carb, which apparently is off one of the other KR models (not sure which one). So I replaced the run of the mill standard fitment Keihin PE26mm with the cool looking PWK with the hope that it ‘should’ give us a little more mojo.

First start up was over the Christmas/New Year holiday. It wasn’t particularly keen to fire up, and when it did it was obvious that the carb settings were way too lean, so off with the carb….shuffle the brass…..back on, and it ran like a dream. Unfortunately though, there were still a couple of critical parts missing (brakes!), so I couldn’t actually test ride it.

Back to Paul…..

As mentioned previously, as well as the building of the bike, there were quite a few products in development at the same time. Luckily, new carbon parts such as consoles, chain guard and rear shock guard went to plan so we removed the brand new plastic Kawa parts for the TYGA carbon ones. We were keen to install the new triple clamp, handlebars and levers. As is often the case with developing new parts, there were improvements along the way for either technical or aesthetic reasons. The 3D printers proved invaluable in this respect. We were able to very quickly mock up the bike using plastic parts to test fit them for clearance and visual reasons. Development moved at a fast pace and these components were either already on sale before the completion of the bike or soon after it.

We took the opportunity to revise the mounting on the stainless exhaust chamber for a more secure installation. This project bike was also treated to a TYGA step kit, filler cap and carbon front fender and everything else that we make for this model. Some observant readers might note that there is still scope for future products such as brake improvements and possibly an upside down conversion. We don’t rule these out but there comes a time when you have to sign off a project and call it done. So for now at least, what you see here is the finished bike.

After first start up the bike had to be left standing for several weeks waiting for the final touches before it could be ridden. Brakes are really an essential component for any road test! Finally the day came and we were able to see if all the hard work and money had paid off. To be perfectly honest, our expectations were not that high, after all, for all its improvements it is still only a budget 150. Matt had first ride just up the lane to check there was nothing amiss and although this was the case, riding impressions were not that well…impressive.

Second ride was mine and I took it for a trundle to the golf course to clean it out without going to bonkers. Immediately I noticed how light it felt and the ergonomics were great for a ‘larger’ rider like me. Surprising for an Asian model. It performed just like a new bike but one with a ring- a -ding pipe. Conscious of the attention it might receive, I took it easy and concentrated on the handling brakes and low down torque. I was expecting it to be a lot rougher low down as this seems to be a characteristic of many 150s but I was pleasantly surprised and look forward to my next proper ride. The final and main ride was Matt’s…

My turn again is it? Let’s turn up the volume.

Anyone that knows me personally knows that I have zero sympathy for motorcycles, so knowing that everything was tight and safe, I wasn’t going to toodle down the road at tickover and declare it good to go.

As soon as I was out of earshot of the locals I started to wind it up a bit. The first thing that sprang to mind was the plentiful midrange (for a 150cc stroker) that it had. It’d pull uphill, from 2,000rpm at full throttle without a hiccup. Useful!

This nice linear power delivery made riding the light and flickable Kawa an absolute breeze through the twisties. No need to dance on the gear lever or rev it to the moon to make decent progress. The suspension was a little soggy, but it’s all stock and I rebuilt both the front and rear, so I guess that’s just the standard feel. The brakes have a nice feel and haul the bike to a stop quickly and in a reasonably stable manner.

So is it fast? Well, as we’re law abiding citizens here at TYGA Performance, we wouldn’t possibly do anything to reach the road regulations, so with my clone on board and a nice straight road ahead, the KRR150ZX was taken to an inch of its life and into the red zone……Hmmmm……Actually not that spectacular to be honest. It seems that top end performance has been traded for zig zagging though Jakata traffic jams. I’d sort of “pre-confirmed” this (is that a word?) when I’d measured the porting as it didn’t seem to be aimed at the top end at all, and this is exactly how it felt.

So to compress that all up into just a couple of lines, the Kawasaki KRR150ZX is a great bike for the town. It’s comfy. It feels super light once on the move and it’s not particularly big. It would be great for stress free riding though busy streets thanks to its smooth and plentiful bottom end.

It’s certainly not the adrenalin charged hooligan stroker that the gossip over the last 20 years had promised, however, there is certainly a lot of potential in that cylinder ????

Set, Exhaust Chamber, Stainless Steel, KRR150ZX

Set, Exhaust Chamber, Stainless Steel, Spring Mounted, KRR150ZX Stainless steel exhaust chamber for KRR150ZX with separate manifold and…

- Model

- EXCS-0035

- Quantity

- 17

Silencer, Carbon/Kevlar, Two Stroke, Assy.

Silencer, Carbon/Kevlar, Two Stroke, Assy. This high quality lightweight silencer (0.47kg) is made from CNC machined end caps joined by…

- Model

- EXSL-0004

- Quantity

- 100+

Air Duct, Carbon, Pair, KRR150ZX

Air Duct, Carbon, Pair, KRR150ZX These carbon air ducts are the same shape as the stock KRR150ZX air ducts.…

- Model

- BPCX-7139

- Quantity

- 3

Rear Shock Guard, Carbon, KRR150ZX

Rear Shock Guard, Carbon, KRR150ZX Protects your rear shock from water and street dirt and adds class…

- Model

- BPCC-7039

- Quantity

- 4

Front Fender, Carbon, Stock shape, Kawasaki KRR150

Front Fender, Carbon, Stock shape, Kawasaki KRR150ZX/KRR150 This direct replacement lightweight carbon version of the stock front fender…

- Model

- BPCF-7039

- Quantity

- 3

Carbon Meter Cover Kawasaki, KRR150ZX

Carbon Meter Cover Kawasaki, KRR150ZX Attractive carbon cover suitable for the KRR150ZX meter assembly.…

- Model

- BPCC-0069

- Quantity

- 8

Front Fork Preload Adjusters, Pair, Kawasaki KRR150ZX

Front Fork Preload Adjusters, Pair, Kawasaki KRR150ZXThese preload adjusters replace the plain fork tops…

- Model

- TYLY-0263

- Quantity

- 100+

Wheel, Front, Aluminium Spacer Kit, KRR150ZX

Wheel, Front, Aluminium Spacer Kit, KRR150ZX Replace the heavy steel rear wheel spacer and wheel bearing distance spacer on the…

- Model

- TPER-0055

- Quantity

- 4

Racing Step Kit, KRR150ZX

Racing Step Kit, KRR150ZX Designed in-house by TYGA Performance using the latest CAD/CAM software, these CNC machine-made step kits are…

- Model

- STAA-0017

- Quantity

- 2

Rear Stand Bobbins, Silver, M10x1.25 Assy.

Rear Stand Bobbins, Silver, M10x1.25, Assy. This item is suitable for any motorcycle with M10 bolt holes for rear…

- Model

- TYLY-0209

- Quantity

- 36

Brake Lever CNC, TYGA, Adjustable, Flip-Up Type, KRR150ZX

Brake Lever CNC, TYGA, Adjustable, Flip-Up Type, KRR150ZX CNC machined from solid billet, these flip up type levers…

- Model

- LEVB-7039

- Quantity

- 84

Clutch Lever CNC, TYGA, Adjustable, Flip-Up Type, KRR150ZX

Clutch Lever CNC, TYGA, Adjustable, Flip-Up Type, KRR150ZX CNC machined from solid billet, these flip up type levers…

- Model

- LEVC-7039

- Quantity

- 85

Triple Clamp Set, CNC Silver, KRR150ZX

Triple Clamp Set, CNC Silver, KRR150ZXCNC machined TYGA triple clamp set for your KRR150ZX.…

- Model

- TYLY-7187

- Quantity

- 2

Handlebar Set, Silver, KRR150ZX

Handlebar Set, Silver, KRR150ZX Direct replacement, CNC machined Handlebars for the KRR150ZX. * the handlebar tubes are…

- Model

- TYLY-0264

- Quantity

- 2

Tank Protector, Universal, H2C

Tank Protector, Universal, H2C This genuine H2C accessory is made from tough flexible plastic with a carbonlook (not real carbon) …

- Model

- APK3317520ZA

- Quantity

- 2

Sprocket, Rear 39T, #428, Stock, Aluminium, (Gold), KRR150ZX

Sprocket, Rear 39T, #428, Stock, Aluminium, (Gold), KRR150ZX Upgrade your bike with TYGA Sprockets.

Designed and machined in house…

- Model

- TYSR-0403-39T

- Quantity

- 22

VHM Cylinder Head KRR150

VHM Cylinder Head KRR150 VHM are a respected manufacturer of high quality racing parts used by factory teams…

- Model

- VHM-KRR150

- Quantity

- 100+

TYGA Bike Dust Cover, Lime Green/Black, NINJA

TYGA Bike Dust Cover, Lime Green/Black, NINJA This cover is handmade from 100% breathable polyester and ideal for an…

- Model

- TMER-0131

- Quantity

- 9